FIEGE installs intelligent picking robots

The logistics company FIEGE has brought two robotic arms online at its location in Greven-Reckenfeld. Two different versions of the automated solution by Nomagic which handle bin picking complexities have been installed at FIEGE.

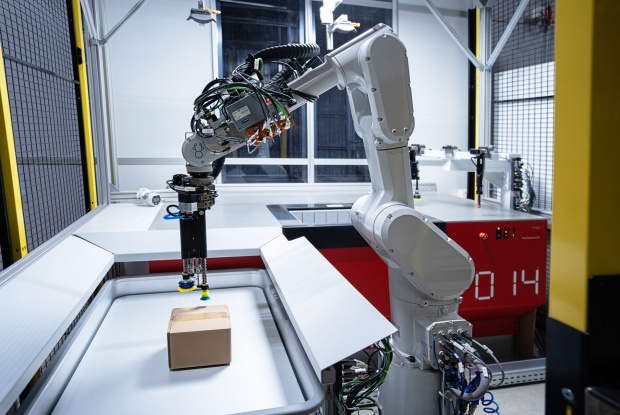

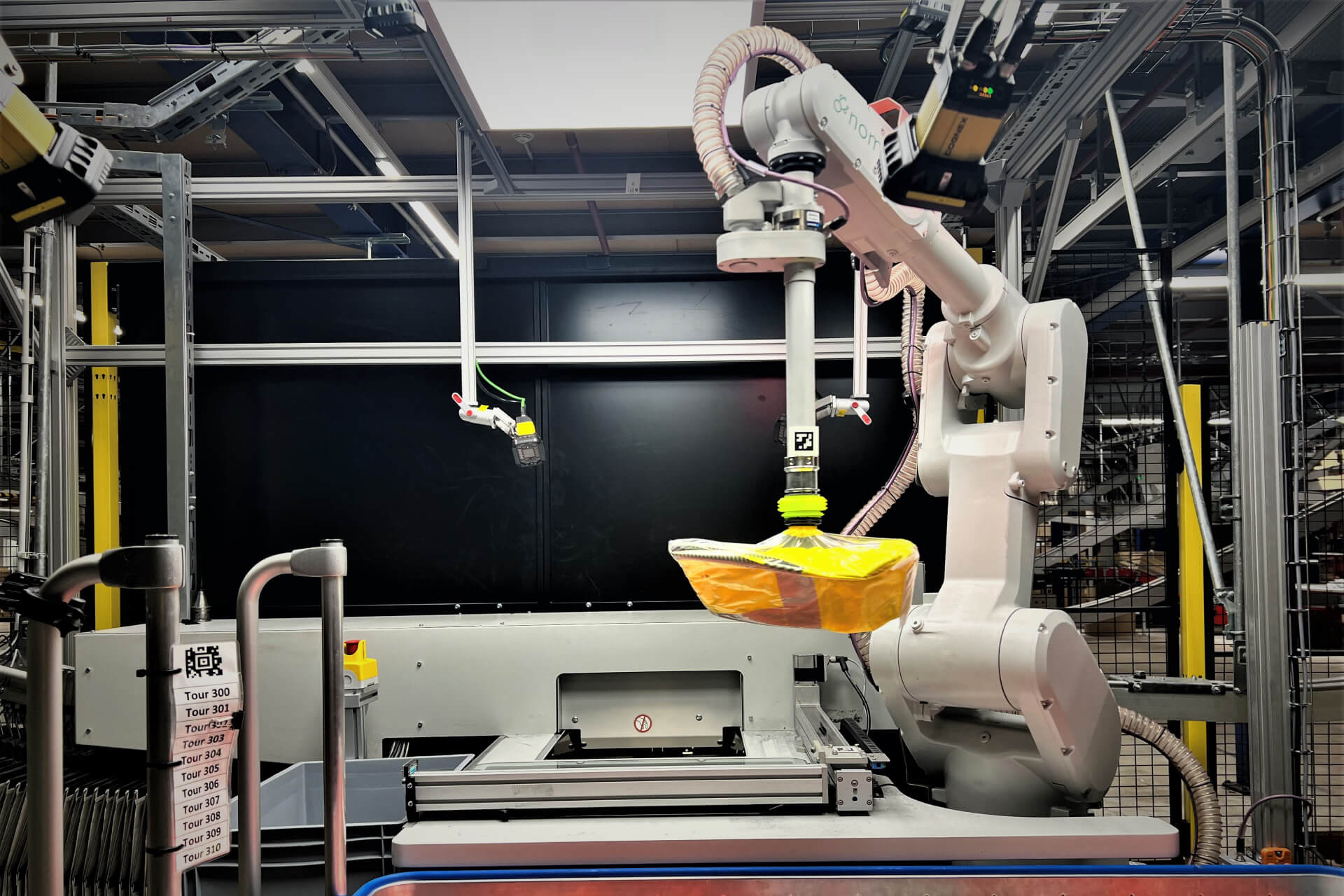

The FIEGE Group continues to drive automation forward at its logistics centres: two intelligent picking robots have been online at its Greven-Reckenfeld branch since mid-December. The two robotic arms have been integrated with two existing automation systems and handle a range of different tasks. While the “justInduct” solution fills a pouch sorter with garments, the “justPick” solution picks and packs tools and consumables at one of the ports of the new Autostore. With the help of this market-ready technology developed by the aspiring robotics company Nomagic, FIEGE aims to increase throughput rates in client processing while at the same time free employees from carrying out repetitive tasks.

Jens Veltel, Director Warehouse Automation at FIEGE says: “We are focused intensely on warehouse automation and have been applying different applications at our logistics centres. The Nomagic team impressed us with their intelligent state-of-the-art solution, which is why we entered a strategic partnership and commissioned the installation of two picking robots. The two high-performance systems recently passed the acceptance test under real-life conditions with flying colours and in the meantime, operations have gone live. We will now look into other optional applications within the World of FIEGE to further roll out the technology.”

Intelligent picking robots: FIEGE has put two robot arms from Nomagic into operation at its site in Greven-Reckenfeld. (Photo: FIEGE)

The robotic arms feature suction grippers which pick and pack any type of item with a minimal failure rate. Pano Papamanoglou, Chief Operations Officer Nomagic explains: “Bin picking remains one of the biggest challenges for the development of robotics. With our case-specific grippers which, as seen at FIEGE, can be switched in no time, robotics arms become suitable for universal application. We are excited to have found a partner in FIEGE who allows us to exploit the full potential of automation of our picking robots, to actively co-create the future in logistical handling.”