FIEGE launches Autostore for Contorion

The logistics company FIEGE has successfully completed the ramp-up for its new Autostore at its multi-user centre in Greven-Reckenfeld. During peak times, the automated system which integrates with robotic and packaging technology, will store up to one million items for Contorion, a tools e-tailer.

The FIEGE Group continues to advance the automation of its logistics sites. At its Greven-Reckenfeld location, the contract logistics expert launched an Autostore for its long-standing client, Contorion. Based on a floor area of 2,500 square metres, the expandable warehouse system is fitted with over 75,000 bins and 35 robots. Special highlights include the integrated 3D packaging machine as well as an intelligent mobile picking robot which independently order picks the tools and consumables at one of the eleven ports.

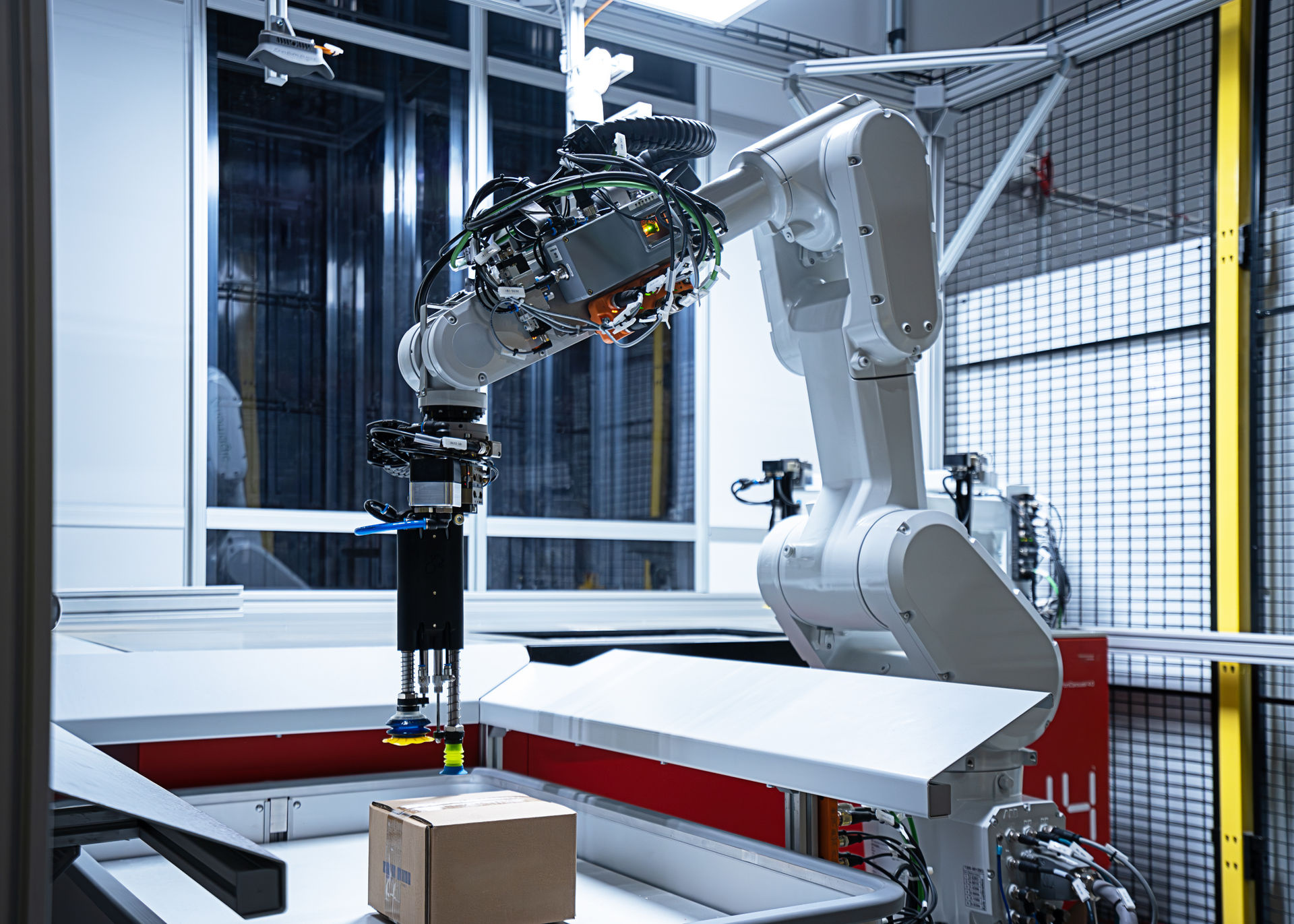

An intelligent pick-and-place robot by Nomagic is connected to one of the eleven Autostore ports, solving the complex issue of bin picking. (Photo: FIEGE)

Stefan Underwood, Head of Logistics at Contorion, explains: “Contorion with its 500,000+ renowned brand products offers the best product range for small and mid-sized enterprises working in trades and in the industry. Order volumes and demand by our clients have grown continually over the past years which is why we decided to optimise our fulfilment. With the installation of the Autostore, FIEGE has created perfect conditions for us to be able to meet orders at short notice while continuing to secure a high level of customer satisfaction.”

FIEGE has been overseeing eCommerce fulfilment for Contorion since 2019. The automation project at the multi-user location in Greven-Reckenfeld is a sustained investment by the family business into the long-term partnership. As Blazej Janik, Manager of the FIEGE Branch in Greven-Reckenfeld, explains: “B2B operations are evolving in a positive direction. The maximum availability of goods and greatest possible throughput capacity are decisive factors for our logistical services. Autostore’s performance is the same compared to what an area of around 10,000 square metres operated under conventional storage conditions can offer. In the future, we will provide a fully-automated solution which will allow us to fulfil the requirements of our client, Contorion even faster and better.”

The ultra-modern 3D packaging system supports the packaging of parcels for Contorion and optimises the use of materials. (Photo: FIEGE)

FIEGE has added conveyor technology as well as an ultra-modern 3D packaging system to the Autostore. One outstanding innovation is the pick-and-place robot, an intelligent robotic arm by Nomagic which, thanks to its suction grippers, reliably grips the items from the picked bins. Meike Schmidt-Krenz, Managing Director at FIEGE's Consumer Products business unit says: “Together with our client, we seek high-performance solutions to tap the full potential of automation at our logistics centres. Our aim, on the one hand, is to increase the throughput for our customer’s processes. On the other, we wish to free our employees of repetitive tasks to be able to deploy them in more demanding and value-creating areas.”