At the height of innovation

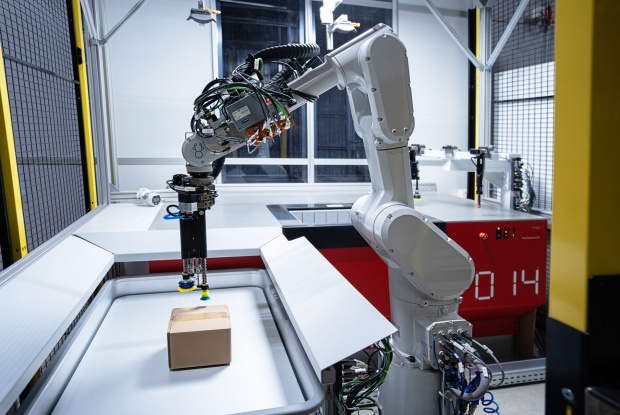

At the FIEGE IDC in Worms, operations are abuzz. On 80,000 square metres of logistics space, our employees turn over some 10,000 parcels packed with power tools on a daily basis. And in the context of an ongoing Proof of Concept (PoC), they have been receiving automated support from driverless floor conveyors.

Being able to forecast the volumes of materials to be handled as accurately as possible is a decisive factor in competition for logistics companies. Employees of the Intercontinental Distribution Centre (IDC) in Worms where FIEGE mainly picks orders for the distribution of power tools know a thing or two about this. “Our line of business deals with extreme seasonal fluctuations. In peak times, we process somewhere around 4,500 euro pallets a day”, says Jens Ritscher, Head of Projects at the branch.

Over the past years in particular, order volumes and therefore the location too, have grown continuously. Meanwhile, some items are picked at twelve metres’ height which is quite demanding on employees. “It goes without saying that we absolutely do not compromise on process safety”, Ritscher explains.

Innovation and experience in sync

At the heart of the IDC is a spacious high-bay racking system. To increase efficiency and ease the physical demands on employees, FIEGE went looking for automation technology at the beginning of the year which would have to meet the special requirements found on location: “We did not want to make any changes to our existing racking system with its standardised dimensions of the individual compartments. Also, the wide aisles are heavily frequented by floor conveyors and the people working there”, is how Jens Ritscher outlines the central challenges when it came to looking for the right technology for on-site support.

The project team (f.l.t.r.): Jens Ritscher, Head of Projects IDC at FIEGE, Jakob Stoffel, System Consultant for automation at Suffel Fördertechnik GmbH & Co. KG, and Jens Veltel, FIEGE Engineering. (Photo: Linde/FIEGE)

After intensely comparing a range of services, the project team in the end opted to do a pilot with Linde MH. The strongest argument in favour of the R-MATIC was the years of experience which the specialist for floor conveyors can show for in this demanding sector. Jakob Stoffel, system consultant for automation with Linde MH’s network partner, Suffel Fördertechnik tells us: “Contrary to what is already thin competition in this sector, our devices are already running as second-generation models so that FIEGE was able to benefit from prior customer projects.”

A focus on occupational safety

In a first step, the Linde MH team digitally mapped the warehouse environment based on which the reach truck can autonomously find its way in the respective environment. Thanks to so-called geo-navigation, the autonomous vehicle can be used as needed without requiring any changes to the existing infrastructure. “One key requirement was also that the R-MATIC is totally safe for people to interact with who work in the three-metres-wide aisles of the racking unit with manual order pickers and regularly cross the path of the R-MATIC”, Stoffel explains. To achieve this, Linde relies on intelligent technology such as an LED warning system, the Linde BlueSpot™, safety laser scanners at foot level, and a 2D curtain laser. As soon as the systems detect an obstacle, the device will first slow down and, if unsure, come to a standstill.

In addition to the autonomous reach truck R-MATIC, a self-driving L-MATIC is also on the road at the IDC in Worms for picking goods on lower shelf levels. (Photo: Linde/FIEGE)

To record a pallet’s exact dimensions, the R-MATIC uses an auto-calibrating 3D camera which ensures placement accuracy even on the top shelving levels. Added safety when working at upper lifting heights is a given with the integrated Dynamic Mast Control assistance which auto-compensates any swinging of the boom. Logistics expert Jens Ritscher points out: “You need to be extremely experienced when using something that reaches more than six, seven metres overhead. On the whole, we were quite impressed by just how relaxed the Linde device operates.”

Decision paid off fast

To be prepared as best as possible when it comes to operating self-acting automation technology, the FIEGE team in Worms underwent comprehensive training. “The goal was to remove any reservations our employees may have. After all, it is not about replacing human skills, but to assist our colleagues in light of a dearth of skilled personnel”, says Ritscher. A mere three weeks after the project started the R-MATIC was already handling its first transits – under real-life conditions, no less, instead of a separate testing environment.

The findings from this pilot are currently being analysed and evaluated. Jens Veltel, FIEGE Engineering explains his first impressions like this: “We noticed that the two machines are a little slower when it comes to storing and removing items compared to our employees but were able to score with high consistency.” Going forward, the devices’ performance under full load-operation and during longer distances in particular will be examined. “It is always our goal to find modular automation approaches that benefit the entire World of FIEGE. For this, we review all parameters that may tell us more about just how broadly we can apply this type of automation in an ideal scenario.”